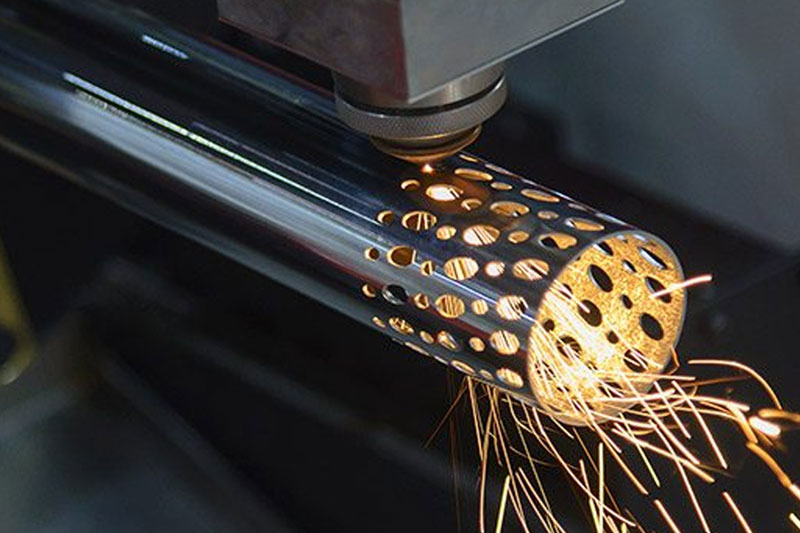

Laser drilling

endox applies three technologies for laser drilling in order to be able to efficiently provide all sizes, i.e. from the micro diameters to large diameters.

Drillings in cannula tubes

(Ø 0,10 mm, 0,15 mm und 0,20 mm)

Single-shot drilling

Here every laser pulse creates a hole. Depending on the geometry of the drilling as well as the properties and strength of the material drillings from 0.025 mm are possible (ratio between wall thickness and drilling 1:20).

Percussion-drilling

Both the laser beam and the shaped part remain in firm position. Depending on the material to be drilled the drilling is carried out by single shot or by continuous shooting. Drillings from 0.025 mm are possible here also depending on the hole geometry and material characteristics (ratio between wall thickness and drilling 1.20).

Trepan-drilling

Controlled by CNC the work piece is navigated circularly under the statically fixed and focused laser beam. Holes with diameters of 0.05 mm are possible (ratio between wall thickness and drilling 1:20).

Precision insert for the construction of apparatus.

Manufacture of a prototype stamping part.

Basic plate of clockwork – please note here the wafer-thin remaining bars.

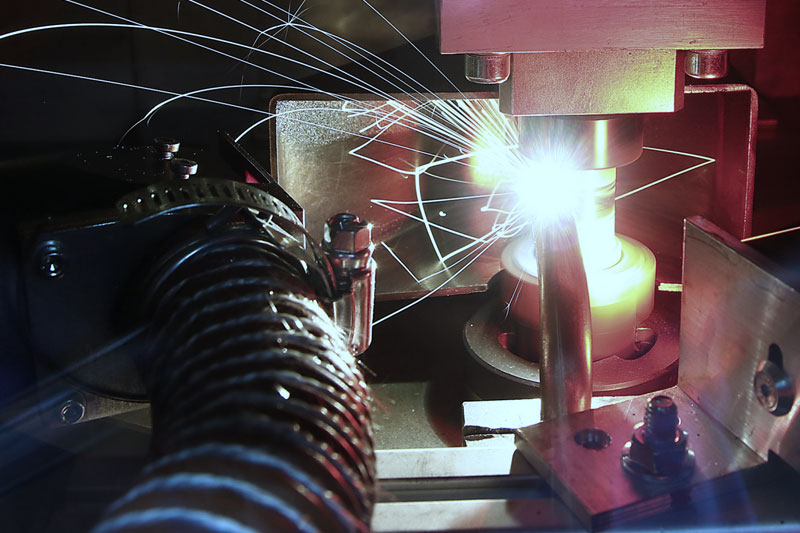

Our LASERDEVICES

consists of modern equipment and machines from LASER TECHNIK

Laser marking

Marking with laser technology offers a wide range of options for signing and labeling.

Laser cutting

Our laser cuts parts from different materials with an accuracy of up to +/- 0.005 mm.

read more

Laser drilling

We use three laser drilling processes to produce everything from micro-boreholes to large boreholes.

read more

Laser welding

Laser welding for precise processing and reduces heating of surrounding material.

read moreAs subcontractors, we produce components and assemblies for customers in almost all industrial sectors - from prototypes to small batch series.